A pipe laser is used by Civil Engineering contractors, builders, and drainage companies to measure the gradient of pipes during the installation of various pipe systems. This could include sewer systems, storm drains, or access points such as manholes. The grade of a pipe is a measure of the pipework’s shape and any dips or elevations that may cause a blockage or slow the movement of liquid through the pipes.

A pipe laser is used to check the grade of a pipe using a high-powered light beam and helps to establish if a pipe system will work efficiently.

How does a pipe laser work?

A pipe laser works by shooting a visible laser down a pipe of up to 300m. Using a combination of geometric calculations and physics, a pipe laser can provide an accurate reading of pipe elevation, which is essential in large-scale underground construction projects. Pipe lasers are helpful for grading, levelling, and alignment and are a great way to reduce human error in construction.

Who can use a pipe laser?

Pipe lasers can be used in some of the most demanding underground construction projects and are generally used by the underground utility industry. This includes public infrastructure, construction, and surveying contractors or businesses.

How to use a pipe laser

Pipe lasers are the best way to establish the grade of pipework. They are simple to use and highly durable to withstand even the trickiest of projects. This is how to use a pipe laser:

- Calculate the grade for your pipe laser by determining the elevation between the two manholes of the pipe you are assessing. You can do this by measuring the distance of each manhole and working out the difference in the elevation. This will give you the ‘run’ and a percentage which determines the grade.

- Set up your pipe laser by inserting it into a pipe as small as 100mm or by using a tripod/trivet plate mount. Imex pipe lasers also come with a variety of screw-in legs to suit many different pipe sizes and give you the flexibility you need for any pipework project.

- Level the pipe laser with the ground either manually using a bubble-level or using an electronic calibration that is built into most modern pipe lasers.

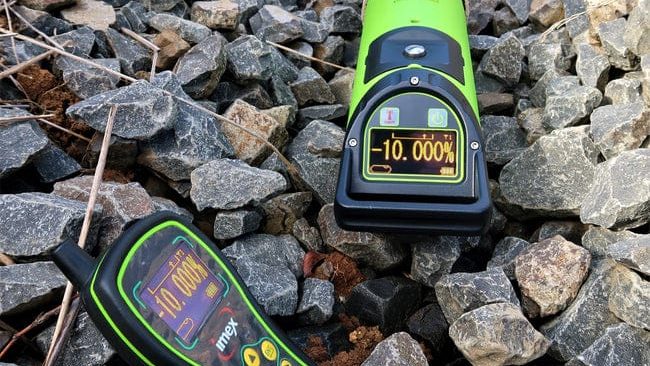

- Set the pipe laser grade using the large backlit display; this will ensure that the laser is shooting down the length of the pipe at the right angle.

- Set your laser target at the opposite end of the pipe. Imex pipe lasers come with this as part of the pipe laser kit.

- Turn on the laser when everything is set up correctly and the laser aligns with the target at the other end. Be careful that the laser does not shoot into anyone’s eyes as this can cause series injury.

- Adjust the laser if needed using the convenient radio remote control.

The benefits of a pipe laser

Pipe lasers have a wide range of benefits and are the best way to ensure you are measuring twice and cutting once with perfect accuracy! The benefits of a pipe laser include:

Size and functionality: The compact Imex pipe laser can be used in pipes as small as 100mm and comes with a hands-free radio control which allows for ease of functionality.

Reduction in human error: A pipe laser ensures consistent accuracy and reduces the chance of human error or incorrect grading/alignment of pipes.

Easy to use: Pipe lasers can be operated by a single person and are simple to set up. The Imex pipe laser has a 24hr operating time and an externally chargeable battery making it a convenient solution to pipe grading.

How to choose the best pipe laser

When choosing the best pipe laser for your project, you should consider a few things:

Beam brightness: Pipe lasers should have a class 3 beam, such as the Imex IPL3G Green Beam Pipe Laser.

Beam colour: Pipe lasers tend to come in two beam colours, green and red. Check out our handy guide for choosing between green and red laser tools!

IP68 rating: As pipe lasers are generally an outdoor tool you need to know that it can keep up with changing conditions. Imex lasers have a fully submersible IP68 rating meaning that they are waterproof and set up for the most demanding tasks.

Gradient function: When choosing a pipe laser one of the most important things to consider is the gradient capability. This should be as large as possible to give you the most accurate reading, for example the Imex pipe laser range has a huge -20% to +40% grade.

Calibration: Correct calibration will ensure that you are getting true readings every time, so look out for laser spot direction settings (either on the device or a remote control) and tracking functions for automatic detection of the target plate.

Range: Ensuring the pipe laser has a strong beam sufficient for the length of drive you are working on is key.

Where to buy the best pipe laser

The Imex IPL3 Beam Pipe Laser is a market leader combining industry-leading features with incredible value for money. Available to order online or through local suppliers. Key features include:

- Interchangeable feet for a variety of pipe sizes

- A huge -20% to +40% grade

- Fully submersible IP68 rating

- Fits 100mm (4″) stormwater pipe

- Electronic levelling

- Auto tracking for target plate

- 8Ah Lithium-Ion rechargeable battery.

- 300m Range

If you would like to know more about our pipe laser range or any other laser tools, contact the Imex team today!